Building refurbishment

Derelict factory building transformed into energy-plus building

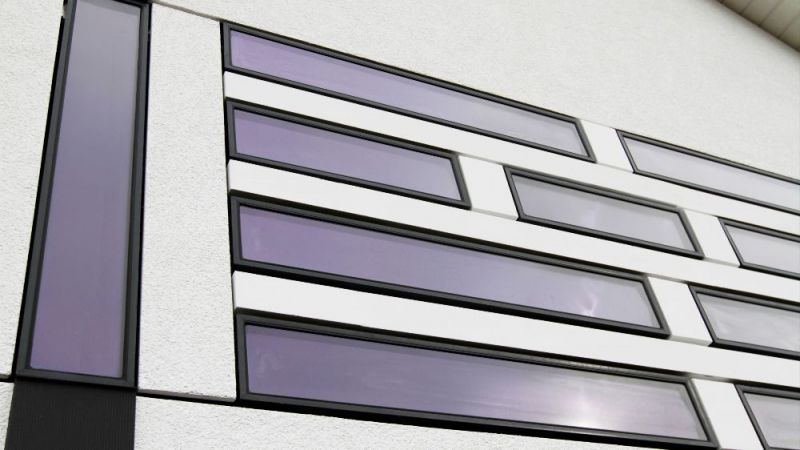

A company from the solar power industry has refurbished a derelict factory building – and with such thoroughness that it has now been transformed into a multifunctional energy-plus building. The developer is now using the building in Hanover as an office building with generous production and storage areas. The office wing has thermal insulation according to the passive house standard. The building is completely heated and air-conditioned using solar electricity, solar thermal energy and wood pellets. The solar power generated considerably exceeds the user demand in the annual balance.

In June 2011, the AS Solar company moved into its new corporate headquarters on Nenndorfer Chaussee in Hanover. The multifunctional energy-plus building was created from a derelict factory building. From Hanover, the 200 employees in the AS Solar Group research, develop and globally market products from the photovoltaic, solar thermal and pellet heating sectors.

The building complex in Hanover originally formed part of the Telefunken company’s Plant II factory, which was built in 1959. TV sets were produced here until the beginning of the 1980s. The industrial building later housed a printing plant. It was then used by logistics companies as a warehouse and car park until the year 2000, and since then has remained empty. The building had very much suffered from vandalism and was actually ripe for demolition.

However, AS Solar had other plans for the building complex, with comprehensive renovation of the building earmarked to begin in 2010. The developer wanted to house offices, production and storage areas in the building for its own purpose. He also plans the construction of a solar gas station at the company location.

Research focus

This research project is aimed at scientifically monitoring the refurbishment of a special non-residential building. An industrial ruin has been exemplarily modernised to provide a multifunctional corporate headquarters with an energy-plus office building. The renovation and energy efficiency measures are being evaluated according to scientific criteria and the building is being optimised during the ongoing operation as part of a two-year monitoring programme.

The intention is to develop and publicise a standardised concept for refurbishing buildings according to the energy-plus standard. This presentation will be supplemented with comparable building schemes and the publication shall therefore be expanded to form a guideline for refurbishments according to the energy-plus standard.

Refurbishment concept

The building is free-standing and consists of two building sections constructed using a reinforced concrete skeleton structure, each with a gently sloped gable-roof structure. In addition to production and storage areas, it was intended to situate about 7,000 square meters of office areas. In addition to an industrial-sized kitchen, cafeteria, two seminar rooms and a technology showroom on the ground floor, office spaces, toilets, showers and recreational spaces are integrated in the intermediate level of the existing building. All office and office-like areas have been executed to the passive house standard. The production area, which has been constructed according to EnEV 2009, is directly next to the office area on the intermediate level. The storage area has been refurbished without any additional thermal protection measures since it shall remain unheated.

The refurbishment design was optimised with a view to using renewable energies. The use of daylight and passive solar thermal gain were increased by providing not only more window areas but also generously sized atria that are located centrally in the floor plans. The daylight usage is further optimised and the requirement for artificial light is reduced by arranging light deflecting devices in the facade areas. The building therefore achieves an energy usage standard that considerably exceeds the current EnEV requirements for existing and new buildings.

Energy concept

The building is heated and cooled using renewable energies. 150 square metres of evacuated tube collectors on the west, south and east elevations support the heating supply, which is provided using a wood pellet boiler system. An already existing, 30 cubic-metre sprinkler tank is used as a heat storage tank. The energy-based refurbishment of the building envelope to the passive house standard, the use of a heating system adapted to the reduced heating needs and the integration of a ventilation system with highly efficient heat recovery have reduced the heating energy requirement by more than 90% from around 270 kWh/m² p.a. to approximately 25 kWh/m² p.a. The office spaces are cooled in summer using a solar thermally powered adsorption chiller with a cooling output of 30 kilowatts. The peak cooling load requirements are covered by a vapour compression chiller with a cooling output of 160 kilowatts.

A photovoltaic plant with a 300-kWp capacity has been installed on the roof. When there is sunshine it provides electricity for operating the building, whereby surplus solar power is fed into the public grid. The waste heat from the inverters is fed into the ventilation system and is used for heating the building. In summer the inverters are cooled with fresh air so as to achieve higher yields from the photovoltaic system. In the second construction stage it is planned to install a further solar power system with a 125-kWp output on a neighbouring warehouse. With the systematic use of renewable energies for heating and air-conditioning combined with the production of electricity using the two large-scale photovoltaic systems, the energy-optimised building achieves an energy-plus standard in the annual energy balance.

Performance and optimisation

Since March 2011, the former Telefunkenwerk II has been used by AS Solar GmbH as a warehouse, production facility and office. The section of the building intended for the cafeteria is currently undergoing renovation. The vapour-compression chiller and the absorption chiller are not in operation due to the fact that there has been no demand for cooling energy yet. Due to the fact that the main building annex has not yet been constructed, and the roof surface is currently lacking, only 268 kWp of the planned 574 kWp of photovoltaic capacity have been put into operation to date.

The preliminary evaluation of building’s performance refers to the measurement period from August 2013 to January 2014:

Heating balance: The solar share of fraction is in the order of 100 per cent as was expected for the first recorded summer month of August 2013. Biomass boilers switch on during the transitional periods and provide almost 100 per cent of the heat during the winter months.

Electricity balance: For the recorded measurement period, the solar share of fraction in August 2013 was about 175 per cent. This means that more power was produced than was consumed.

Project data

| Building owner, Operator and Occupant | AS Solar GmbH |

| Year of construction | 1959 |

| Inauguration | 03.2011 |

| Gross floor area | 13.000 m² |

| Heated net floor area | 7.055 m² |

| Gross volume | 53.332 m³ |

| Work places | 250 Personen |

| Usable floor area (according to EnEV) | 17.066 m² |

| A/V ratio (before / after renovation) | 0,34 / 0,31 m²/m³ |

| Energy indices demand | |||

|

Energy indices according to EnEV, sc. according to DIN 4108-6 or DIN 18599 calculated. Reference plane is in each case the heated net floor area according to DIN 277. |

|||

| after refurbishment |

before refurbishment |

||

| Heating energy demand (utility energy demand heat) | 25,00 | 270,00 | kWh/m²a |

| Primary energy heat | 94,20 | kWh/m²a | |

| Overall primary energy | 163,30 | kWh/m²a |

| Renovation cost | |

| Net costs according DIN 276 related to the gross floor area (GFA) according to DIN 277, Establishment of total cost | |

| Costs for the (renovation of the) structural design [KG 300] | 409 EUR/m² |

| Costs for the (renovation of the) technical installations [KG 400] | 219 EUR/m² |

09.11.2021