Energy concept for supermarket

Energy-efficient supermarket utilises daylight and ground cooling

Aldi Süd is testing its “energy saving store of the future” with its new supermarket in Rastatt, Germany. Here the discount supermarket chain wants to save 30 per cent of its energy relative to standard supermarkets. This is only possible by sensibly combining numerous individual measures relating to the cooling, refrigeration units, building envelope and building services technology. Aldi Süd intends to incorporate those concept components that prove themselves in the pilot project into its standard building specifications when building new supermarkets or refurbishing existing ones.

Aldi Süd constructs or refurbishes around 100 stores each year in Germany, whereby it consistently relies on a uniform quality standard that is reflected in both the architecture and the system technology used in the supermarkets. Energy efficiency and comfort have long been issues addressed by the store developers. According to Aldi Süd, the utilisation of waste heat from the commercial refrigeration systems is just as much standard as the ventilation systems with heat recovery and the comprehensive energy monitoring. With its new store in Rastatt, Aldi Süd once again intends to increase the energy efficiency of its supermarkets by a considerable and exemplary amount, whereby it is endeavouring to achieve primary energy savings of 30%.

Research focus

At frequent intervals, the data from more than 200 sensors and measuring devices are transferred daily to the Fraunhofer Institute for Solar Energy Systems where they are evaluated. This is because the operation of the supermarket is being analysed and optimised as part of a two-year scientific monitoring phase. A central aspect is concerned with evaluating the innovative CO2 cooling system and the interaction between the different components under varying operational conditions. Also important is the control of the pressure and temperature levels on the high-pressure side of the system.

The same applies to the temperature levels of the thermally activated concrete slab and ventilation system, since they have a considerable impact on the energy efficiency and thermal comfort in the supermarket. The thermal coupling with the ground is being analysed in terms of energy-related and economic criteria in order to evaluate the additional investments required for constructing the geothermal system. The daylight system and the daylight-dependent artificial light control are being analysed and optimised to improve the energy efficiency and to achieve optimal visual comfort for the customers.

Building concept

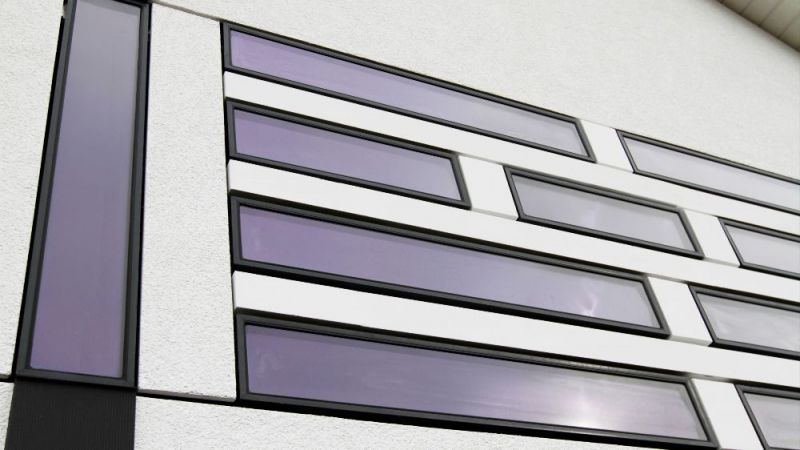

The new building has been designed and constructed as a very energy efficient building. Although from the outside it looks almost identical to Aldi Süd’s standard stores, there are considerable differences in terms of the system technology used and the building structure. The supermarket has facades made of highly insulated precast concrete panels and an innovative roof structure made of glued-laminated timber trusses. A blower door test showed that there are less than 0.5 air changes per hour.

The daylight is provided by 28 skylights that are evenly distributed above the sales space. The triple glazing used for these skylights is furnished with a frit pattern in the inter-pane cavity, which reflects the direct solar radiation and enables views of the sky. The timber roof cladding is visible and enables excellent light distribution in the room. Low thermal bridging and airtight construction were ensured during the planning stages.

Energy concept

A central element of the building’s energy concept is the monovalent and geothermally supported CO2 compressor pack. It is designed to supply the entire heating and cooling, enabling other heat generators or air conditioning systems to be entirely eliminated. Specifically, the system provides commercial cooling at three different temperature levels: in the chiller cabinets and freezers in the sales area, in the cold stores in the storage area and for ambient cooling. In addition, it also provides space heating.

The ventilation with heat recovery provided as standard by ALDI was optimised in terms of the air volume and efficiency. The air volume is controlled in accordance with the CO2 to achieve the hygienically minimum air volume. Heating and cooling is provided via a thermo-active floor slab in the sales and storage areas and via underfloor heating in the recreational area. The supply air is also pre-heated and pre-cooled via the compressor pack system. The individual sub-systems have to be adapted to the refrigeration pack during both their design and operation to enable its maximum possible use.

The operation of systems with CO2 as the heating or cooling medium is not without problems. An important aspect in ensuring the high efficiency of CO2 systems is to avoid trans-critical operation. With high external temperatures, the cooling medium is therefore cooled as much as possible. Compared with other cooling media, carbon dioxide has a lower critical temperature of 31 °C. This is a decisive factor for its energy efficient processing, since above the critical point carbon dioxide can no longer be liquefied, even under greater pressure. In addition, the temperature with which the carbon dioxide is released from the heat exchanger is decisive for the energy efficiency. The lower the temperature, the higher the achievable coefficient of performance, which measures the energy efficiency. It is intended to achieve this by integrating a borehole heat exchanger, which has lower heat sink temperatures, into the compressor pack system. In winter the borehole heat exchanger will be used as a heat source for a heat pump switching system integrated within the compressor pack system. In order to ensure that the borehole heat exchanger is cost effective and remains operational in the long term, the ratio between the heat removal and heat influx for the ground has to be balanced out across the year.

Performance and optimisation

The primary energy consumption for cooling, ventilation, heating, air conditioning and lighting in 2012 was 387 kWh/m2a after climate adjustment, about 5% below the previous year's value and 23% below the consumption of a standard branch, but does not reach the planning targets. The greatest savings effect compared to 2011 was achieved with 10% in the lighting systems. Optimisation measures in the refrigeration system reduced energy consumption by 3%. An analysis of thermal comfort showed that good indoor comfort could be achieved in the supermarket in both winter and summer.

The refrigeration system, which was initially very conservatively controlled, was supplemented with outside air temperature-dependent control of the high pressure in subcritical operation. This increased the energy efficiency in refrigeration, but the target value of 256 kWh/m2a was not achieved. Further optimisations in the design of important components and in the switching of the different refrigeration points have already been implemented in a second generation of a similar refrigeration system in another supermarket. The first measurement results there show that the target values can be achieved.

For the lighting systems, the specific primary energy consumption in the first year of operation was 101 kWh/m2a, about 22% above the target values set in the planning. This was largely due to the fact that originally planned schedules were not adhered to. Instruction of the operating staff by the supermarket operator brought about significant energy savings.

In the area of hydraulics, energy consumption was reduced by using smaller pumps. The time control of the ventilation system was adapted more precisely to the actual shop operation.

Economic efficiency

Due to the new energy concept, the operational costs for the building services systems have been calculated to be around 35% less than for a standard store.

Note: In KG 400 user specific assets are includes, see table "Implementation costs".

Project data

| Building owner | Aldi Süd Rastatt GmbH | |

| Building type | Supermarket | |

| Time data | ||

| Year of construction | 2010 | |

| Completion | 08.2010 | |

| Commissioning | 09.2010 | |

| Area sizes/dimensions | ||

| New building | ||

| Gross floor area (according to DIN 277) | 1.825 m² | |

| Gross volume | 9.054 m³ | |

| Usable area AN (according to EnEV) | 1.675 m² | |

| A/V-Ratio | 0,56 m²/m³ |

| Energy indices according to German regulation EnEV (in kWh/m2a) |

||

| New building |

||

| Heating demand (useful energy demand heat) | 82,00 kWh/m²a | |

| Total final energy (according to DIN V 18599) | 216,00 (Strom) kWh/m²a | |

| Overall primary energy requirement | 79,60 kWh/m²a |

| Net construction costs | ||

| (according to German DIN 276) relating to gross floor area (BGF, according to German DIN 277) | ||

| Construction (KG 300) | 718 EUR/m² | |

| Technical system (KG 400) | 332 EUR/m² | |

| These figures represent established costs |