CO2-neutral campus

University building with an innovative energy system

With the new-build scheme, Erfurt University of Applied Sciences is expanding its traditional “green campus” with a particularly energy-efficient teaching and laboratory building. The use of district heating combined with an adsorption heat pump enables a rainwater cistern to be used as a renewable heat and cooling energy reservoir in combination with the utilisation of waste heat from the central computer technology system. The new building is the first scheme as part of the Erfurt University of Applied Sciences’ aim of achieving a CO2-neutral campus.

With this building, it is intended to expand the 13-hectare “Green Campus” at Erfurt University of Applied Sciences with a modern, new-build scheme. It will house a new lecture theatre and laboratories for the Landscape Architecture and Horticulture faculties. The need for a new building was established back in 1998. Based on a development concept that was consequently drawn up by PAD Baum + Freitag + Leesch, Gerber Architekten from Dortmund were commissioned to come up with a design in the year 2000. However, the entire project then stalled. In 2008, the project was brought back to life, whereby the client now specified new, more ambitious aims for the building and energy concept. It is now intended that the lecture theatre and laboratory building shall meet the demanding energy requirements for model projects conducted as part of the EnOB research initiative. In cooperation with scientists from FH Erfurt, architects and specialist designers have conceived a future-oriented building with an energy-optimised building concept.

Research focus

As with all EnOB model projects, the building will undergo close scientific monitoring once it goes into operation, whereby all the main material and energy flows will be recorded and balanced over a period of two years. A particular focus in this regard will be on the interplay between the various components used in the innovative energy system. The key to achieving an optimal interaction is deemed to be a perfectly matched room and system automation. It will therefore be investigated whether the automation concept defined in the planning phase can ensure energy efficient operation.

By using a rainwater cistern as both a heat source and heat sink, the potential offered by this innovative application is being examined, since the combined use of ground water and cistern water provides a new alternative to other processes for tapping environmental energy sources.

Based on the measured energy flows, it will also be more precisely determined whether the use of the adsorption heat pump, which is driven by district heating, provides economic and primary energy benefits. The utilisation of the waste heat derived from the central IT equipment and indoor environment as well as the user satisfaction will also be closely examined.

Building concept

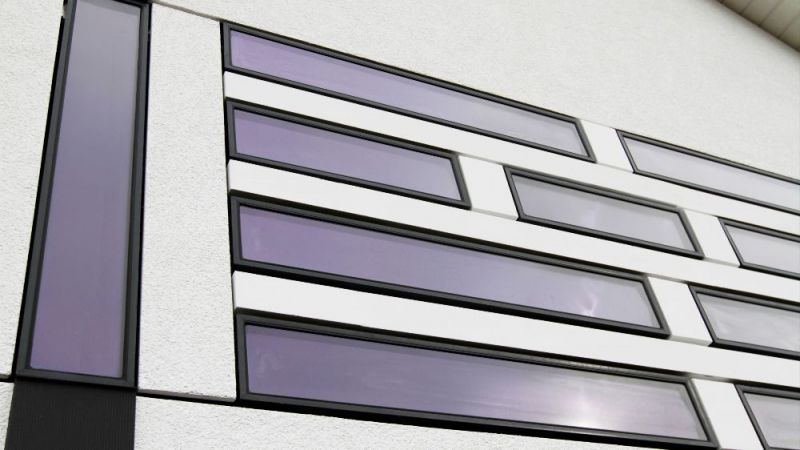

The integration of the building into the landscape and the incorporation of the new building into existing structures served as a basis for the architectural design concept. The new, three-storey building is situated to the rear of the campus.

ourtyard areas will be created between the existing buildings and the new building that are sunk into the ground along the lower ground floor of the new building, which is actually beneath ground level. These enable the rooms to face outwards with generous openings and be naturally lit. They also provide the lecture theatre, the public spaces on the lower ground floor of the new building and the existing cafeteria in the old building with an attractive setting that is enhanced by the greened courtyard and terraced steps that provide seating. The new building therefore only appears to have two stories and thus maintains the proportions of the existing buildings. A single-storey connection building leads from the new building between the two existing buildings to form a joint main entrance.

The building houses 18 offices and 54 PC workstations. The two lecture halls and the three seminar rooms can accommodate a total of 208 students.

665 students from the faculty use the building, which has a usable floor area of almost 1,000 square metres. A high-quality room provision with seminar and work rooms, two lecture theatres, two laboratory rooms and a computer pool will be available in a location that is more than just a place serving knowledge transfer: the university building is already suitable as a research subject for students in accordance with the project-oriented teaching based on the principles of sustainability.

Energy concept

The building has to be designed as a very energy efficient building. Specifically, it is intended that the primary energy requirement will not exceed 60 kWh/m²a and will therefore undercut the limit value specified by EnEV by almost 50%. This will be achieved by means of consistent thermal protection and a harmonised range of different energy technologies.

The entire building envelope will be very well insulated: in addition to the facade (U-value 0.166) and the roof (0.133), all building components adjacent to the ground will also be insulated (0.166 to 0.132). The stringent requirements for the windows and the mullion-and-transom structure will be met with a triple-glazed timber-aluminium structure. For the transparent areas, it is planned to have a U-value of 1.0, a g-value of 0.58 and a flexible, external solar shading system, which will result in an overall g-value of 0.145.

A very effective measure for saving primary energy is the adsorption heat pump, which is driven by district heating and uses a rainwater cistern as a renewable heat source. A ground water well provides a supplementary backup system. The system functions as follows: a tube heat exchanger contained in the cistern draws heat required for the building from the cistern and thus from the surrounding ground. In combination with an adsorption heat pump driven by district heat (based on water/lithium bromide), the thermal energy from the cistern is raised to a usable temperature level. The adsorption heat pump draws heat from the rainwater cistern down to a temperature of around 8 °C and stores this in a stratified storage tank in the boiler room. If the cistern temperature is less than 8 °C, the building is directly heated with district heating. The building is cooled in a similar way using the same system. This makes it possible to dispense with the use of a conventional vapour-compression chiller. The waste heat from the IT technology equipment can also be used in winter for heating purposes.

The heat is transferred to the rooms using thermo-active building systems (TABS) in the form of suspended ceilings. This enables both heating and cooling. Separate radiators beneath the windows are not required. The large heat transfer surfaces enable higher cooling media temperatures and lower hot water temperatures to ensure a comfortable indoor environment and high energy efficiency.

Vacuum insulation panels (VIPs) are used on the building structure to prevent thermal bridges at neuralgic points.

The concept for the ventilation systems is based on specific application requirements. The lecture rooms and laboratories are ventilated in accordance with the indoor air quality using mechanical ventilation systems, a heat recovery system and speed-controlled fans. The single offices are individually ventilated using window ventilation.

The various sub-systems are incorporated into an integrated control concept in order to further optimise the energy efficient operation. It is intended that the building operation will be consistently and continuously adapted to the actual requirements, whereby presence and air quality sensors as well as quickly responding heating and cooling elements will be deployed.

LED technology is being used for lighting in the circulation areas.

Performance and optimisation

Experience gathered during the first year of operation in 2013 shows that the installed heating and cooling surfaces make for a comfortable indoor environment despite the low temperature differences. The users are satisfied with the building. However, the building services that deviate from the normal case apparently did require some explanations.

In the first year of operation, the building reached the target values for the heating requirement. In contrast, the consumption of electrical energy in this period was 90 per cent higher than the design value. The electricity requirement for lighting alone exceeds the design value by 200 per cent.

After a first optimisation measure, the heat pump now achieves a thermal performance factor of 1.15, which corresponds to a 13 per cent reduction in consumption. The electricity requirement to operate the circulation pumps of the heat pump system is not negligible. Further optimisation potential is to be tapped in the further course of the project.

The cooling of the computer rooms achieves electrical performance factors from 9 to 15. The rainwater cistern and the ground water are used very efficiently for renewable cooling purposes.

During the commissioning of the building, some serious faults were found in the components of the building services equipment and sensor technology, and in the implementation of the control concept. For example, there was a defect in the adsorption heat pump, leading to a failure of heat meters, individual devices were incorrectly connected, the measuring data of the CO2 sensors in the teaching units were faulty and the operational management did not correspond to the design concept. Looking back, it becomes clear that the integration of the innovative components and a fault-free implementation of the automation and control concept in particular places very high demands on the participants in the construction process in terms of expertise and timing.

| Who is who? | |

| Building owner | Freistaat Thüringen, Thüringer Ministerium für Bildung, Wissenschaft und Kultur |

| Investor | Freistaat Thüringen gefördert aus Mitteln des Europäischen Fonds für Regionale Entwicklung |

| Operator | Fachhochschule Erfurt, Dezerant Bau und Liegenschaften |

| Occupant | Fachhochschule Erfurt, Fakultät Landschaftsarchitektur, Gartenbau und Forst |

| Building type | University and laboratory building |

| Year of construction | 2012 |

| Completion | 2012 |

| Inauguration | 2012 |

| Measures | |

| Gross floor area | 2.237 m² |

| Heated net floor area | 1.844 m² |

| Gross volume | 8.889 m³ |

| A/V ratio | 0,43 m²/m³ |

| Energy characteristics Demand | ||||

| New building / after … | before refurbishment | |||

| Heating energy demand | 57,08 | kWh/m²a | ||

| Source energy for heating and domestic hot water (dhw) | 25,59 | kWh/m²a | ||

| Overall primary energy requirement | 61,25 | kWh/m²a | ||

| Measured energy consumption data (in kWh/m2a) | ||||

| New building / after … | before refurbishment | |||

| Primary energy demand for heating (demand values) | 29,00 | kWh/m²a | ||

| Primary energy demand for ventilation (demand values) | 45,81 | kWh/m²a | ||

| Site energy for heating and domestic hot water (dhw) | 38,60 | kWh/m²a | ||

| Primary energy demand for lighting (demand values) | 82,18 | kWh/m²a | ||

| Total source energy | 125,89 | kWh/m²a | ||

| further specific consumption data for lighting, air conditioning, ventilation, etc. | ||||

| New building / after … | before refurbishment | |||

| Electricity for artificial lighting | 12,78 | kWh/m²a | ||

| Electricity for air handling units | 9,79 | kWh/m²a | ||

| Electricity for pumps including development of environmental energies | 3,50 | kWh/m²a |

| Net construction costs (according to German DIN 276) relating to gross floor area (BGF, according to German DIN 277) | ||||

| Construction (KG 300) | 1.257 | EUR/m² | ||

| Technical system (KG 400) | 486 | EUR/m² | ||

| These figures represent established costs | ||||

Operating costs |

||||

| New building / after … | before refurbishment | |||

| Total energy costs | 10,00 | EUR/m²a | ||

| Total heating consumption | 3,00 | EUR/m²a | ||

| Total electricity consumption | 7,00 | EUR/m²a |

22.11.2021