New-build factory

Zero emissions for climate-neutral production and management

The new-build scheme housing the production and administration facilities for one of Germany's leading solar companies relies on 100 % renewable energy sources. Consistently planned to save energy, the heat requirement of 23 kWh/m² p.a. is 80 per cent below the requirements stipulated at that time for conventional industrial new-build schemes by the 1995 German Heat Insulation Ordinance (WSchV 95). The remaining primary energy requirement is met by combining solar power and biomass as energy sources. This enables a “zero-emission factory” to be realised in the annual balance. The building has been awarded numerous prizes.

Project context

The contractor wanted production and administration together under one roof, with the objective of economical workflows and production processes, as well as short communication channels. Comfortable workplaces with daylight, and continuously pleasant indoor temperatures, as well as appealing architecture made from environmentally friendly construction materials, were also on the long wish-list, as was a completely renewable energy supply. To put it briefly, the new building was to unite functionality, aesthetics, and environmental friendliness. But the really significant goal was the zero-emission factory, i.e. a building which, with regard to the annual balance, causes no CO2-equivalent emissions. To this end, renewable energy sources provide heat and electricity.

Building concept

The building encompasses all areas of use in a compact building structure. One striking feature is the exterior steel support structure, which serves as a substructure for the active solar systems. The production area is thus not obstructed by vertical supports, and is flexibly utilisable. At the same time, the heated air volume is reduced by 15%. For reasons of load transfer and thermal storage capacity, the corridor area and the walls of the offices are made of reinforced concrete. The flat roofs and walls of the production hall are structurally optimised, very well insulated, lightweight construction elements with wooden frames. The ribbon windows in the hall are equipped with thermally insulating double glazing. The facade of the offices consists of high, thermally insulating triple glazing, some of which with obscure glass. The opening casements are wooden panels with vacuum insulation. Outdoor two-section venetian blinds provide protection against overheating in summer.

Already before construction work commenced, the building won the Innovation Prize for Architecture in 2001. This was later followed by the European Solar Prize, the Architecture & Technology Award, and finally the Energy Globe.

Energy concept

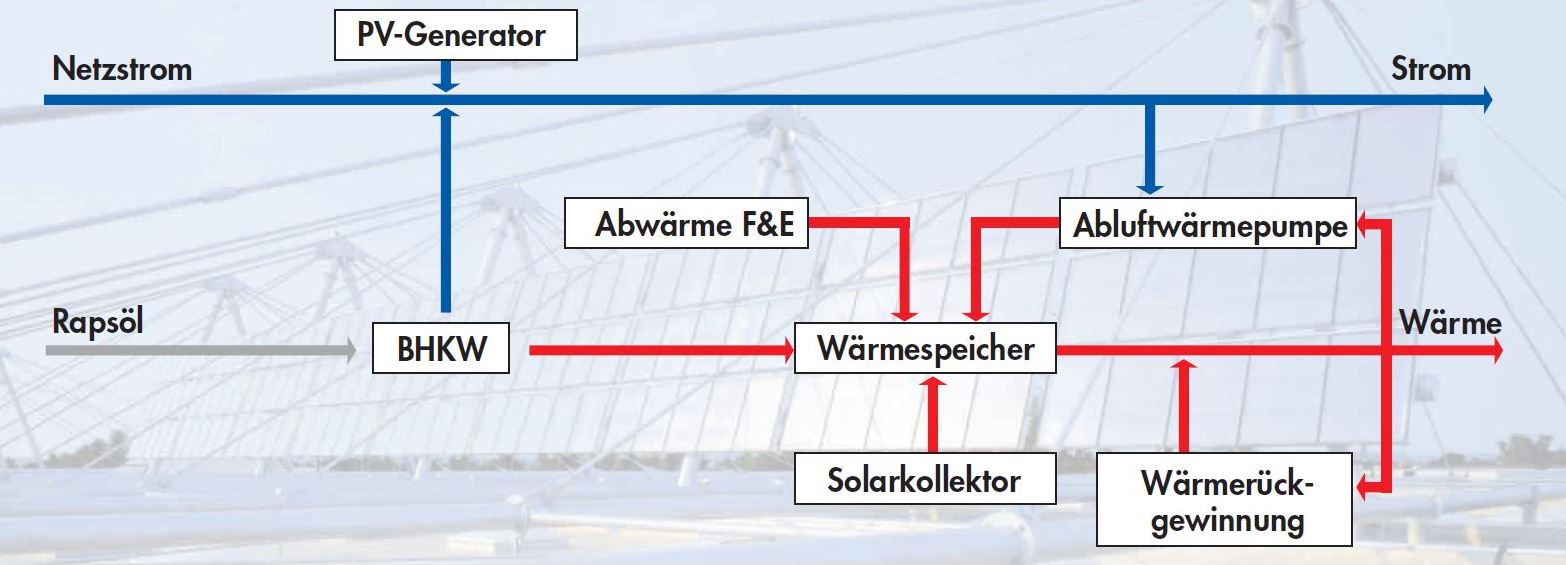

Electricity: in order to cover the building's energy requirements in a CO2-neutral manner, electricity is supplied by a rapeseed oil combined heat and power plant, and a photovoltaic system, from which any surplus is fed into the mains grid. The PV system is limited to 600m², both economically and structurally, and its capacities also set the limits for the maximum possible electricity demand to be covered in a CO2-neutral manner at 12.5 kWh/m² p.a.

Heat: the CHP plant, the solar thermal collectors, and the waste heat from the boiler testing equipment, which is also fed into the buffer storage tanks, cover the building's heating requirements. In addition, the sprinkler system's tanks store the heat from the solar thermal system, and at the same time perform a radiant heating function in the hall. Also the waste heat from the IT centre serves to support the heating of the warehouse in winter.

There are two different heating systems for production and offices: the halls are economically heated by means of ventilation with heat recovery. The offices are heated via individually adjustable radiators. An additional ventilation system in the offices guarantees high quality indoor air in winter, and serves for passive cooling via overnight ventilation in summer. Here, there is a simple exhaust air system with heat recovery via an exhaust air heat pump.

The production hall receives generous amounts of daylight via a multitude of skylights, and via ribbon windows in the facade. Via an outdoor brightness sensor, the artificial light is automatically dimmed, depending on the daylight. The installed capacity is 8 W/m² for a nominal illuminance of 200 lx in the warehouse, and 300 lx in production. Individual areas have additional workplace lighting. The offices are lit naturally via observation windows, and light-scattering frosted glazing above the observation areas. Venetian blinds, which divert daylight in the upper area, provide a combination of sun protection and glare protection.

Performance

The factory building is exemplary due to its environmental approach and its architecture. Construction measures and technical measures have made it possible to minimise the energy consumption at 28.9 kWh/m² p.a. (heat) and 25.1 kWh/m² p.a. (total electricity). Thus, the building's energy values are far below today's standard values.

The primary energy balance between consumption and production is not actually level yet. As the waste heat from the development department is incorporated into the heating concept, energy consumption is always coupled to operation of the factory. Here, boiler testing caused more waste heat than was expected at the planning stage, and this heat replaced heat from the CHP plant. Thus, the CHP plant generated a correspondingly lower amount of electricity. As a result of this, together with several other factors, the zero-emission principle was not quite reached in 2004.

The data analysis enabled a series of optimisation proposals and error corrections, primarily regarding pump operation and software control. Further optimisation potential resides in the following areas: reduction of the ventilation systems' electricity consumption, consistent implementation of energy-saving office equipment (computers and monitors), and optimisation of the functionality of exhaust air flaps and ventilation valves.

Construction costs and profitability

Despite the fact that lofty energy technology ambitions (zero-emission principle) and an attractive industrial architecture have been achieved, the building was planned and constructed at a relatively low cost.

18.11.2021

Service provider

Trainings- & Weiterbildungszentrum Wolfenbüttel e.V

http://www.tww.de

info@tww.de

Tel.: +49(0)5331-939-780-20