Living Lab for the energy transition GWP

River Heat Pump in Mannheim Supplies Climate-Friendly Heat

Mannheim is one of five power plant locations that are part of the living laboratories for the energy transition “Large-scale heat pumps in district heating networks – installation, operation, monitoring, and system integration” (GWP). In this project, the various operators install large-scale heat pumps with different heat sources in existing district heating systems. The goal is to advance the decarbonization of heat supply. The German Federal Ministry for Economic Affairs and Climate Action (BMWK) is funding the project with around € 21.3 million.

At the commissioning ceremony in Mannheim at the beginning of October, Christian Maaß, Head of Directorate-General II for Heat, Hydrogen and Efficiency at BMWK, said: “The river heat pump is a successful example of transformation in heat supply and shows the role that large-scale heat pumps can play in green heat networks in the future.” By using the new system, up to 10,000 tonnes of CO2 can now be saved annually in Mannheim.

Official commissioning of the MVV river heat pump with, among others, Christian Maaß, Head of Directorate-General II for Heat, Hydrogen and Efficiency at the German Federal Ministry for Economic Affairs and Climate Affairs (2nd from left) and Gerard Uytdewilligen, GKM Technical Director (2nd from right).

Around 700 litres of Rhine water per second

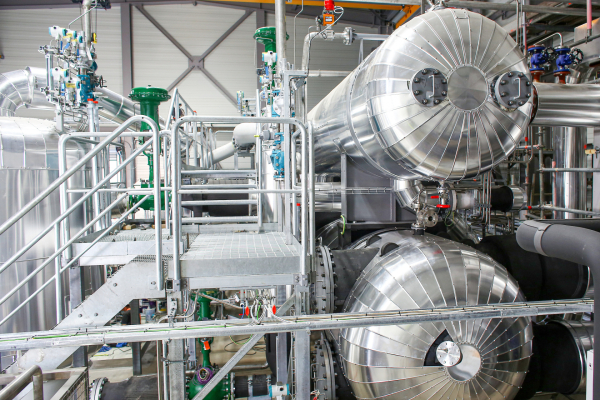

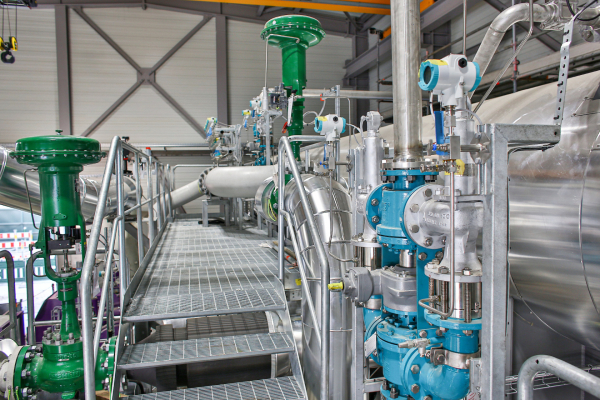

The fact that the heat pump in Mannheim was integrated during ongoing operations was a challenge: “Special timing and tact were required when integrating the system into our control technology, when installing the new Rhine water pump with the associated piping and fittings in the existing cooling water pump house, and when laying the pipes for the Rhine water and the district heating,” says Gerard Uytdewilligen, Technical Director of GKM AG.

Now, the climate-friendly heat can be fed both into the existing district heating storage facility and directly into Mannheim’s district heating network. The heat pump also uses the existing cooling water infrastructure. This means that around 700 litres of Rhine water per second can be used as a heat source.

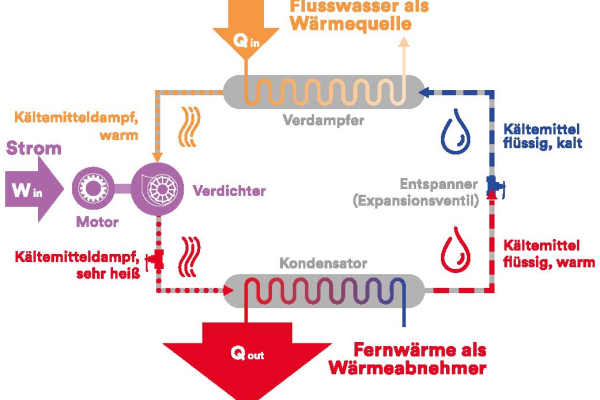

Functional principle of the river heat pump

The water from the river Rhine in Mannheim reaches temperatures of up to 25° Celsius in summer and about 5° Celsius in winter. These temperatures are sufficient to evaporate the refrigerant in the heat pump, cooling the extracted Rhine water by around 2° to 5° Celsius. The refrigerant vapor is then compressed with the aid of an electricity-driven compressor so that the pressure and temperature rise. The heat generated by the refrigerant vapour is transferred to the district heating water by condensation in a heat exchanger: hot water with a temperature of between 83° and 99° Celsius can be produced in this way. In the meantime, the refrigerant liquefies again and is expanded again before reaching the river water heat exchanger. In the process, it cools down and, at a low temperature, absorbs thermal energy from the river water again – and the cycle begins all over again.

Investigations continue

In the living lab for the energy transition GWP, the project partners want to find the best way of using large heat pumps in heating networks. “On the way to green, climate-neutral district heating, technologies of this kind form an important basis,” says AGFW Managing Director Werner Lutsch. “Together with other energy sources such as biomass, solar thermal energy, waste heat, or deep geothermal energy, river heat pumps will in future ensure that an ever-greater proportion of district heating comes from climate-neutral sources.” The AGFW-Projekt GmbH coordinates the living lab for the energy transition GWP.

Even after commissioning, research continues in Mannheim. During regular operation, the experts collect additional data. These help refine the technology and driving modes as well as enable regulatory learning.

Living labs for the energy transition put innovations into practice

Funded by the German Federal Ministry for Economic Affairs and Climate Action, the living labs for the energy transition test innovative technologies in practical applications under real conditions and on an industrial scale. Experts can then use the experience gained in the projects to decisively advance the far-reaching transformation of the energy system in Germany toward climate neutrality.

On the topic of “energy-optimized neighbourhoods, ” five other living labs for the energy transition have already been launched in addition to GWP:

DELTA – Darmstadt Energy Lab for Technologies in Application

JenErgieReal – Energy-optimized living lab using real-time scalable energy storage systems

IW3 – Integrated heat turnaround Wilhelmsburg

SmartQuart – Smart energy districts

Five living labs for the energy transition have also already been launched in the area of “sector coupling and hydrogen technologies”. An overview of all projects and further information on the topic can be found at energieforschung.de.