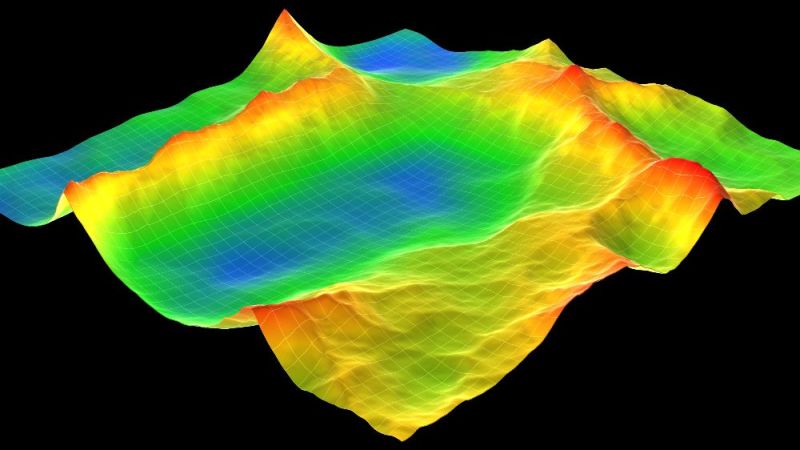

Tests in the storage lab

Making Pit Thermal Energy Storage More Efficient

We need a cover! Those of us with even a small swimming pool in our garden will quickly arrive at this conclusion, as it is important to keep the water as clean and as warm as possible. But what does the perfect cover look like? This question is also being posed for pit thermal energy storage systems, as the heat being stored needs to be retained for as long as possible.

Pit thermal energy storage systems are multifunctional

Pit thermal energy storage systems are artificial pools in which a large pit is sealed off from the soil, insulated, filled with water, and given a floating cover. The water can be heated by various heat sources, for example solar collectors or waste heat. The hot water, which reaches temperatures of up to 95 degrees Celsius, charges the storage system. At times when there is limited radiation from the sun or waste heat available, the storage system releases this heat again. Long-term thermal energy storage systems buried in the earth were originally developed as part of solar heating networks. Today, they mostly serve as multifunctional thermal energy storage systems, storing heat from various sources for several days or, if required, from summer until winter. They also enable sector coupling between the supply of electricity and heat.

A cover on top of the thermal energy storage system minimizes the loss of heat. In addition, it protects the water in the storage system from external influences such as precipitation and pollution. The team behind the Efficient Pit project (focused on the development of highly efficient pit thermal energy storage systems for heating networks) is investigating materials and optimizing the design of the floating cover. The cover must offer good insulation and long-term durability as well as being temperature-resistant, light, stable, and inexpensive.

Efficient Pit team to build its own storage lab

The various layers of the cover act as insulation, a vapour barrier, and a drainage layer. The Efficient Pit researchers aim to investigate the various strengths, compositions, and arrangements of these layers. They will look at the cover as well as the temperature-resistant plastic waterproof sheeting that lines the floor and walls of the storage system. Project participants from the Solites Steinbeis research institute and Solmax Geosynthetics GmbH are also planning to construct a thermal energy storage system for the purpose of testing. “In our storage lab, we will be able to analyse the differently constructed layers and plastic waterproof sheeting as part of durability tests. Our installation teams will be able to handle, assemble, and weld the sheeting under real-world conditions. This will allow us to analyse and improve various designs within the entire system,” explains Thomas Labda, Project Manager and Key Account Manager Renewable Energy at Solmax.

How quickly does the temperature-resistant sheeting deteriorate?

In addition, laboratory testing will be conducted to see how the temperature-resistant plastic waterproof sheeting deteriorates over time. This will involve material samples being exposed to high pressures and temperatures in autoclaves and furnaces. The Efficient Pit team will also conduct deformation tests to see how stable the artificially deteriorated materials are.

The researchers will also apply a bright signal layer to the black plastic waterproof sheeting. The signal layer will allow the installation team or industrial divers to detect possible damage at an early stage during inspections. In conjunction with a control system, a leak detection layer will also reveal any potential leaks.

The information website www.saisonalspeicher.de will also be relaunched over the course of the four-year project, with the project’s R&D findings being summarized on this knowledge platform.

Storage research for over 25 years

Across Europe, there are around 20 long-term thermal energy storage systems with various designs. This includes eight pit thermal energy storage systems that were built over the last few years, predominantly in Denmark. The world’s largest storage system of this kind can currently be found in Denmark and covers a volume of 200,000 m³. This type of storage system is particularly used for thermal energy storage systems with large volumes of over 50,000 m³ that are buried in the earth, as it represents the most cost-efficient design.

Long-term thermal energy storage systems buried in the earth have been the subject of research for more than 25 years. As part of the Solarthermie2000 and Solarthermie2000plus national funding programmes, experts from Solites co-developed a number of the thermal storage systems originally built for seasonal storage as well as overseeing their construction and subsequently evaluating their operation.

In the futureSuN project, researchers looked at these systems after long periods of operation and verified their durability and reliability. “Further research and development is needed in order for the multifunctional use of thermal energy storage systems to take the next big step as part of the heat transition. In the Efficient Pit project, we want to develop tools for pit thermal energy storage systems that ensure our findings can be applied and are accessible to the market,” explains Dirk Mangold, head of the Solites Steinbeis research institute and head of the long-term thermal energy storage systems working group. This working group was established in 1999 and serves as an exchange platform for experts. (KStr)